Cleveland Circuits specializes in Flexible Circuits, often referred to as Flex or Rigid Flex.

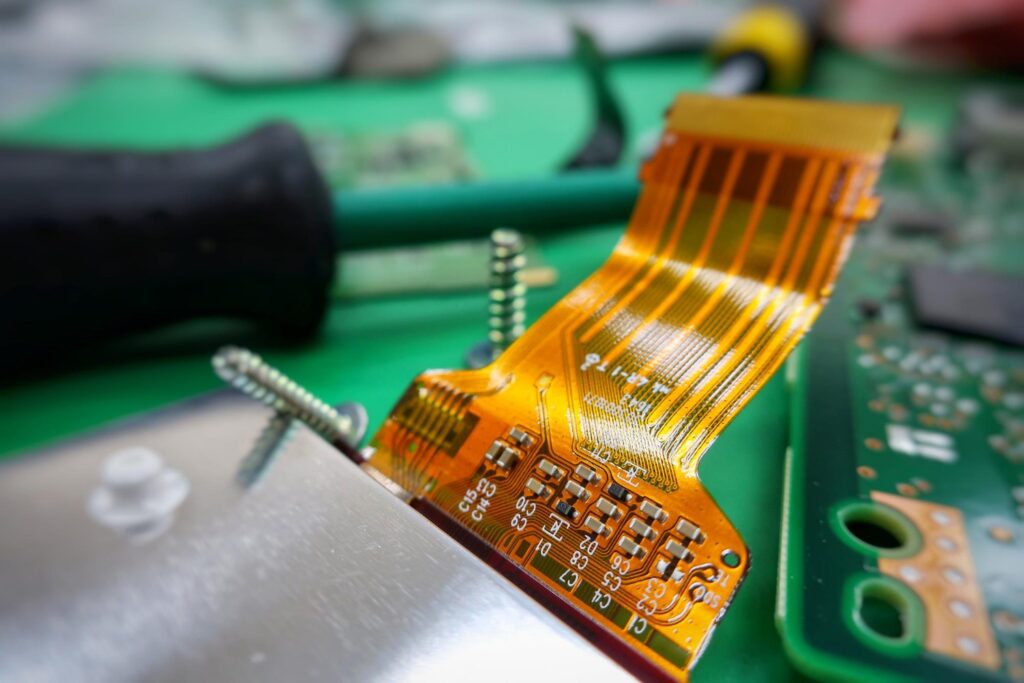

A Flex PCB is commonly manufactured using a Polyimide laminate and varies in thickness from 0.001″ to 0.020″. Rigid Flex is a flex circuit sandwiched between two rigid PCB’s.

Cleveland Circuits has the ability to manufacture flexible circuits up to 28″ in length, with a lead time as little as 5 days. Flexible circuits are ideal for any application that needs to have a small foot print or needs the ability to continually bend during operation.

Industries that we serve are Aerospace, Medical and Automotive applications.

Cleveland Circuits works directly with flex material manufacturers, therefore skipping the traditional distribution chain. This relationship allows us to achieve a more competitive price structure for complex flex technologies.

Contact one of our specialists today and find out why Cleveland Circuits should be your Flex PCB Manufacturer.

- Substitute for Bulky Wire Harnesses: Flex PCBs offer a streamlined alternative to cumbersome wire harnesses, reducing weight and saving space.

- Replacement for Hardboard/Connector/Cable Assemblies: Use rigid-flex or flex with stiffeners to replace traditional hardboard, connector, and cable assemblies.

- Flexible Shields or Ground Planes: Flex PCBs can be designed with conductor patterns to act as shields or ground planes, reducing electrical noise and interference.

- Enhance High-Speed Signal Integrity: Matched-impedance flex circuits are ideal for maintaining signal integrity in high-speed applications.

- Miniature Jumpers on Circuit Boards: Flex PCBs can be used as miniature jumpers, providing reliable connections in compact and intricate circuit designs.

2. Benefits of Flex Technology

- High Reliability: Flex PCBs are designed for dependable performance in various applications.

- Repeatable Installations: Ensures consistent and accurate installations every time.

- Harsh Environments: Ideal for use in extreme conditions, providing durability and stability.

- High Vibration: Capable of withstanding high levels of vibration without compromising performance.

- Consistent Electrical Characteristics: Conductor patterns maintain uniform electrical properties, ensuring predictable noise, crosstalk, and impedance.

- Reduced Assembly Cost: Lowers production costs by simplifying the assembly process.

- Replacement for Circuit Board and Wires: Acts as an efficient substitute for traditional circuit boards and wiring systems.

- Reduced Weight and Space: Offers significant weight and space savings, ideal for compact designs.

- Dynamic Flexing: Suitable for applications requiring continuous or repetitive flexing.